Home » Innovation » Radiant cooling technology

RADIANT COOLING TECHNOLOGY

Implementation of Radiant Cooling Technology & integration with Central Command Center at Infosys EC 53 Building, Bangalore

INFOSYS EC 53 Building, Bangalore

OBJECTIVE

-

Optimum Energy Use

-

Improved Comfort

-

Operational Efficiency

-

Lower Breakdown

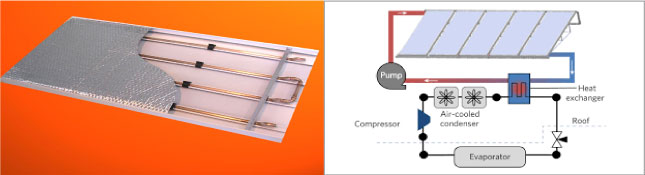

Radiant Cooling system works on radiation & convection heat transfer, using Radiation as technology and Water (3400 times more cooling than air) as medium for cooling. Radiation is the fastest mode of heat transfer (^4 faster than conduction & convection)

RADIENT COOLING

Radiant system works on radiation & convection heat transfer.

Between conduction, convection and radiation, radiation is the fastest mode of heat transfer.

It is ^4 faster than conduction and convection.

Use Radiation as technology and Water (3400 times more cooling than air) as medium, as compared to Convection and air as medium for cooling.

-

Just 1/4th Air Compared

To Conventional System -

30% More

Efficient -

Superior Indoor

Air Quality -

Superior Thermal

Comfort

| Medium | Specific heat | Density |

|---|---|---|

| WATER | 4.2 kj/kg deg K | 1000 kg/m3 |

| AIR | 1.0 kJ/kg deg K | 1.25 kg/m3 |

| Medium | TR | Quantity | KW |

|---|---|---|---|

| WATER | 100 | Approx 240 US GPM water required | 3.7 KW |

| AIR | 100 | Approx 40000 Cfm air Required | 22 KW |

RADIFLUX

-

Convential Central Cooling

-

Radient Concrete Slab Cooling

-

Radient Panel Cooling

-

RADIFLUX

Patented Infosys in-house development

India’s first Radiant Building.

KNND partnered with Infosys to implement Radifluxdriven projects in it’s offices across India, covering

over 10 Lac square feet of installation

Significant savings in cost & energy